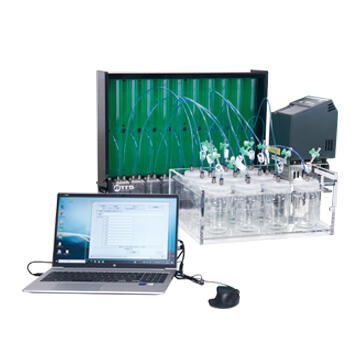

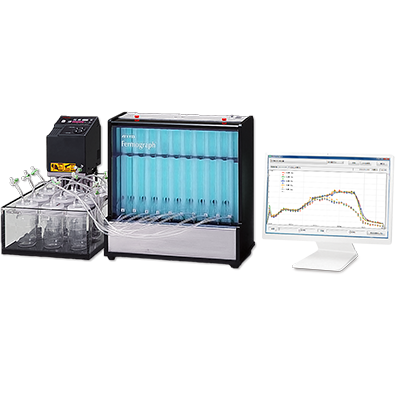

WSF-2000 MH Fermograph III

In the realm of biotechnology and food science, the WSF-2000 MH Fermograph III stands as an indispensable tool, empowering researchers and industry professionals to delve into the intricate world of fermentation processes. This sophisticated system meticulously measures and monitors gas production during fermentation, providing valuable insights into microbial activity, substrate utilization, and overall fermentation efficiency.

Harnessing the Power of Gas Measurement

The WSF-2000 MH Fermograph III transcends mere observation, transforming gas production data into actionable knowledge. Equipped with advanced pressure sensors and temperature sensors, this system continuously records gas volume, gas production rate, and gas quantity produced in the dough, enabling researchers to gain a comprehensive understanding of fermentation dynamics.

Unveiling Fermentation Profiles with Precision

The WSF-2000 MH Fermograph III caters to a wide range of sample types, including bread dough, sake, yeast culture solution, and bioethanol production medium. Its versatility extends to measuring samples that produce gas in a short period of time, such as baking powder.

A Versatile Tool for Diverse Applications

The WSF-2000 MH Fermograph III's adaptability finds applications in a broad spectrum of disciplines, including:

- Baking Science: Evaluate dough fermentation kinetics and optimize bread baking processes.

- Biotechnology: Assess microbial activity and optimize fermentation conditions for bioethanol production.

- Food Science: Monitor fermentation processes for sake, kimchi, and other fermented foods.

Features that Empower Scientific and Industrial Advancements

The WSF-2000 MH Fermograph III boasts a range of features that empower scientific and industrial advancements:

- Simultaneous Measurement of Up to 20 Samples: Efficiently monitor multiple fermentation processes simultaneously.

- Automatic Data Recording and Storage: Seamlessly capture and store fermentation data for in-depth analysis.

- User-Friendly Interface: Navigate the system with ease using the intuitive interface.

- Export Data to Various Formats: Export data to CSV and other formats for further analysis and sharing.

Demystifying Fermentation Dynamics with the WSF-2000 MH Fermograph III

In the intricate world of fermentation, the WSF-2000 MH Fermograph III emerges as a beacon of clarity, illuminating the dynamic interplay of microbial activity, substrate utilization, and gas production. This sophisticated system meticulously monitors gas production during fermentation, providing researchers and industry professionals with invaluable insights into the fundamental principles that govern this transformative process.

Unveiling the Secrets of Microbial Activity

The WSF-2000 MH Fermograph III transcends mere measurement, transforming gas production data into a window into the metabolic symphony of microbes. By continuously tracking gas volume, gas production rate, and gas quantity produced in the dough, the system unveils the metabolic pathways employed by microorganisms, providing insights into their growth, enzyme production, and energy utilization.

Unraveling the Mysteries of Substrate Utilization

The intricate dance of fermentation involves the transformation of substrates into energy and products. The WSF-2000 MH Fermograph III provides a deep understanding of substrate utilization by tracking gas production alongside changes in substrate concentration. This comprehensive data allows researchers to optimize fermentation processes, maximizing product yield and minimizing waste.

Optimizing Fermentation Efficiency

The WSF-2000 MH Fermograph III revolutionizes fermentation monitoring, enabling researchers and industry professionals to optimize fermentation efficiency and achieve optimal product quality. By meticulously measuring and analyzing gas production data, the system provides valuable insights into fermentation kinetics, allowing for adjustments to fermentation conditions, substrate composition, and microbial selection.

A Versatile Tool for Diverse Industries

The WSF-2000 MH Fermograph III's versatility knows no bounds, catering to a wide spectrum of industries and applications:

- Baking Industry: Evaluate dough fermentation kinetics and optimize bread baking processes for better texture, shelf life, and flavor.

- Bioethanol Industry: Assess microbial activity and optimize fermentation conditions for bioethanol production, maximizing yield and reducing production costs.

- Food Industry: Monitor fermentation processes for sake, kimchi, cheese, and other fermented foods, ensuring consistent product quality and enhancing flavor profiles.

Empowering Innovation and Advancements

The WSF-2000 MH Fermograph III has transformed the field of fermentation monitoring, empowering researchers and industry professionals to gain a deeper understanding of fermentation processes and unlock new possibilities for innovation. Its comprehensive capabilities, user-friendly interface, and adaptability make it an indispensable asset for those seeking to optimize fermentation efficiency, develop new products, and advance the frontiers of biotechnology, food science, and brewing.

With the WSF-2000 MH Fermograph III as their guide, researchers and industry professionals embark on a journey of innovation, unraveling the secrets of fermentation and unlocking its transformative power for the betterment of our world. From optimizing baking processes and enhancing food quality to advancing bioethanol production and developing new fermentation-based products, the Fermograph III empowers a world of possibilities, driving advancements in various industries and contributing to a more sustainable and prosperous future.

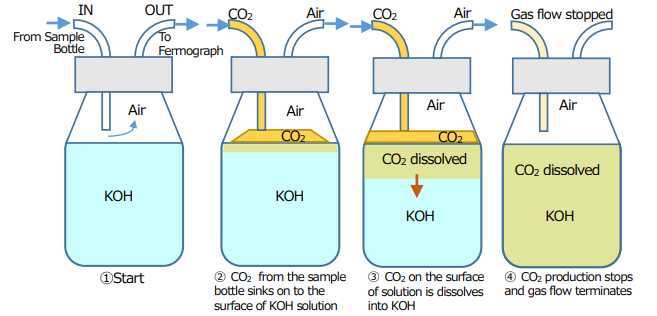

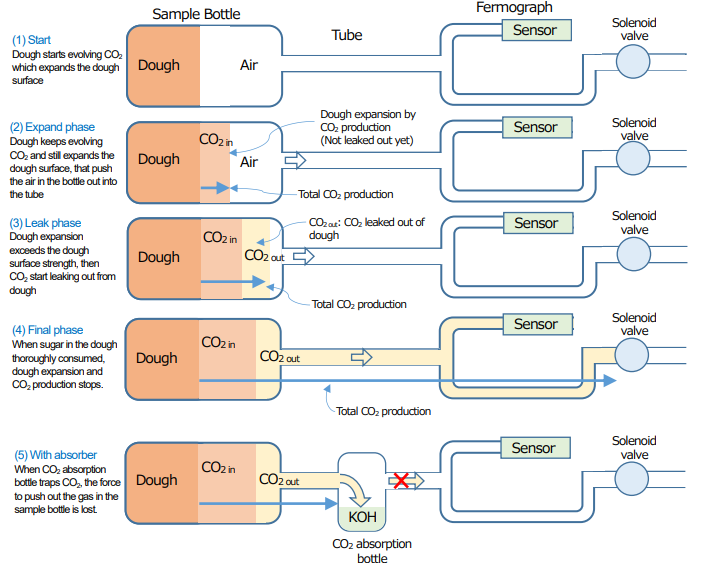

[Understanding Retained and Leaked Gas Measurement in the Fermograph System]

The measurement of retained and leaked gas in the context of bread dough study can be intricate at times. To provide clarity, here are some perspectives elucidating the measurement process for your reference.

Gas Movement within the Sample Bottle and CO2 Absorption Bottle

CO2 Production in the Sample Bottle

CO2 Absorption Bottle

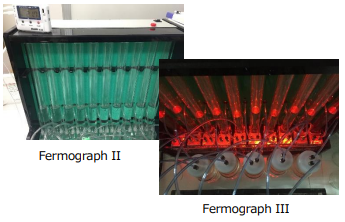

Having been developed over two decades ago, Fermograph II was designed using sensors, components, and software selected at that time. However, some of these parts have been discontinued, and their accuracy and stability may not meet current technological standards. In contrast, Fermograph III has undergone a comprehensive renewal, incorporating the latest components, including sensors used in medical devices for COVID-19 patients. This upgrade ensures enhanced measurement accuracy, stability, and reproducibility compared to its predecessors.

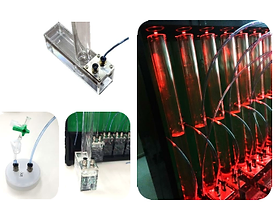

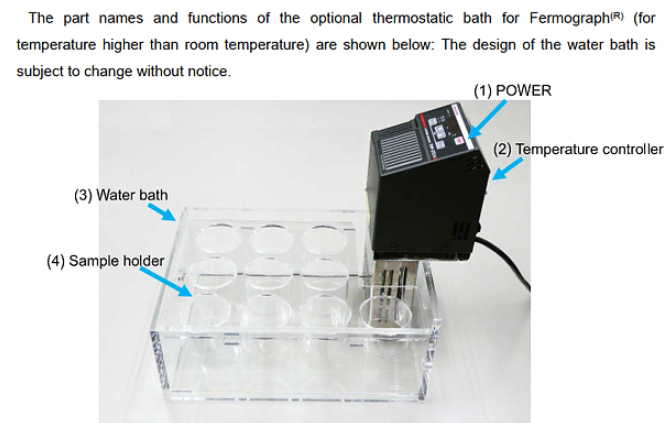

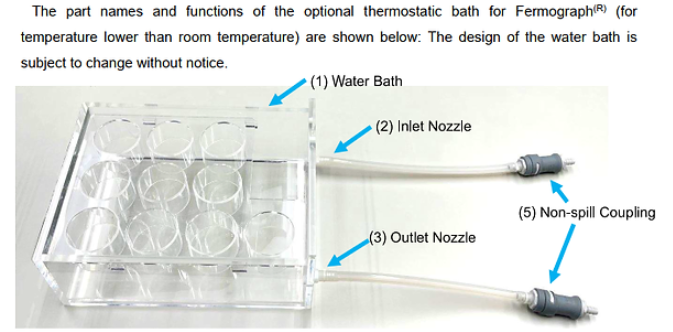

Thermostic Bath

Thermostic Bath without nozzles / with temperature controller

Thermostic Bath with nozzles / without temperature controller

Within Fermograph III, a red LED is positioned atop each manometer cylinder to enhance the visibility of the liquid level. This feature simplifies the monitoring of liquid levels during extended overnight measurements and provides a clear indication of the power supply status (LED illuminates when ON).

Conclusion

The WSF-2000 MH Fermograph III has revolutionized fermentation monitoring, providing researchers and industry professionals with a powerful tool to gain valuable insights into fermentation processes. Its versatility, ease of use, and comprehensive range of features make it an indispensable asset for those seeking to optimize fermentation efficiency, develop new products, and advance the frontiers of biotechnology and food science. With the Fermograph III as their guide, researchers and industry professionals embark on a journey of innovation, unlocking the secrets of fermentation for the betterment of our world.